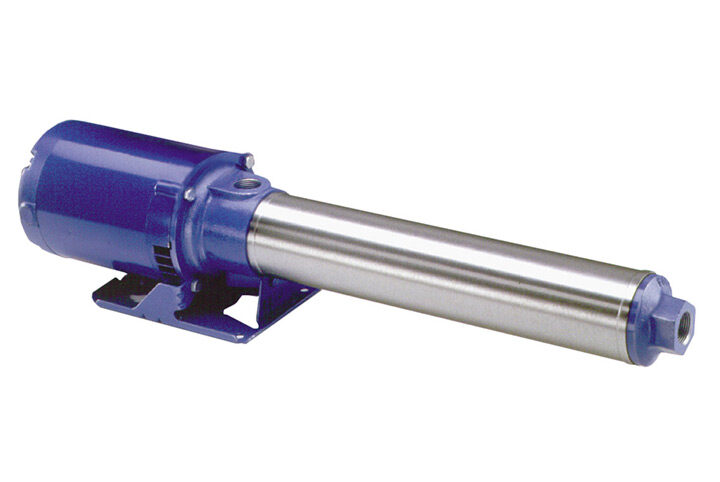

Regenerative Turbine Pumps

MTH has combined sixty years of water passage design with a multistage mechanical concept to achieve maximum capacity and pressure while minimizing horsepower requirements. By optimizing the number of pumping stages with each water passageway, MTH improves both efficiency and pressure in the 140 • 240 • 180 • 280 Series, exceeding the standards realized by previous techniques.

Typical Applications:

Hot Water Pumping

Low NPSH

Boiler feed service

Water Passage Design

MTH masters one of the most critical design considerations for regenerative

turbine pumps — the shaping of water passageways to achieve

highest capacity and pressure while minimizing horsepower requirements.

By optimizing water passageway cross-sectional profiles for each impeller, MTH has improved both

efficiency and pressure in the T51 • E51 Series, and exceeds the levels, realized by previous techniques.

Impeller Profile

One of the most notable improvements in regenerative turbine pump technology incorporated in T51

• E51 Series pumps involves the ability to determine the optimum

impeller width and blade length. These factors have a significant effect on the required horsepower versus

pressure curve for regenerative turbine pumps. By optimizing these for each T51 • E51 Series pump, peak efficiency is improved and “off

peak” horsepower requirements are reduced as well.