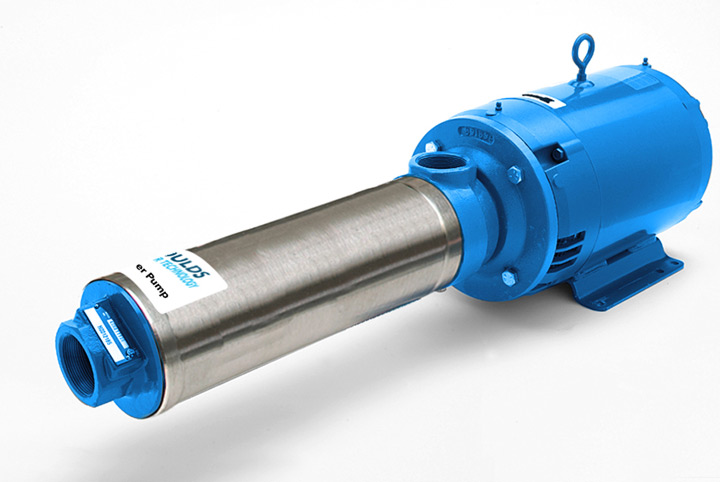

Goulds HB Multi-Stage Centrifugal Bosster Pump is a great addition to irgation systems that require efficiency and power.

GOULDS HIGH PRESSURE CENTRIFUGAL BOOSTER PUMP

This Goulds HB Multi-Stage Centrifugal Bosster Pump Design: This configuration provides a steady, quiet and vibration-free operation for years of trouble- free service.</div

Impellers and Diffusers: Glass filled thermoplastic. Precision molded for high efficiencies.

Bowls: Constructed with 300 series stainless steel. Rabbet lock for positive alignment – no gaskets required.

Mechanical Seal: Carbon/ceramic faces. BUNA elastomers 300 series stainless steel metal parts.

Motor: Close-coupled design. Ball bearings carry all radial/axial thrust loads. Designed for continuous operation. All ratings are within working limits of the motor.

45HB, 70HB HIGH PRESSURE CENTRIFUGAL BOOSTER PUMP

PRODUCT APPLICATIONS SPECIFICATIONS

Wide variety of industrial, commercial and agricultural Pump

uses, especially:

• High rise buildings

• Multiple dwelling buildings • Reverse osmosis systems

• High pressure cleaning

• Spraying systems

• Booster service

SPECIFICATIONS

Pump:

• Capacities: to 100 GPM

• Heads: to 760 feet.

• Pipe connections: Suction 2″ NPT, Discharge 2″ NPT.

• Temperature: 160ºF (71ºC) maximum.

• Inlet pressure: 100 PSI maximum.

• Rotation: right hand, i.e., clockwise when viewed from

motor end.

Motor

• Open drip-proof or TEFC enclosure 60 Hz, 3500 RPM.

Threaded shaft extension.

• Single phase: 3 HP 115/208–230 V

5 HP 208–230 V

7½ HP 208–230 V.

• Three phase: 3–10 HP 208–230/460 V.