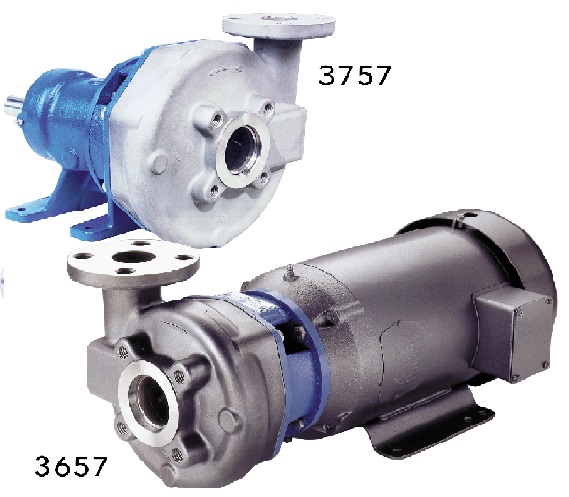

GOULDS 3657/3757 Stainless Steel Pumps

ICS – A FULL RANGE OF PRODUCT FEATURES

- Superior Materials of Construction: Precision invest-ment cast 316 stainless steel liquid end components for corrosion resistance and strength.

- Frame Mounted Design: Flexibility of installation and driver arrangements.

- Open Impeller Design:Spherical handling to 3⁄8” reduces chance of clogging and required maintenance time.

- Back Pull-Out Design: Simplifies maintenance by allowing the casing to remain in the piping during disassembly.

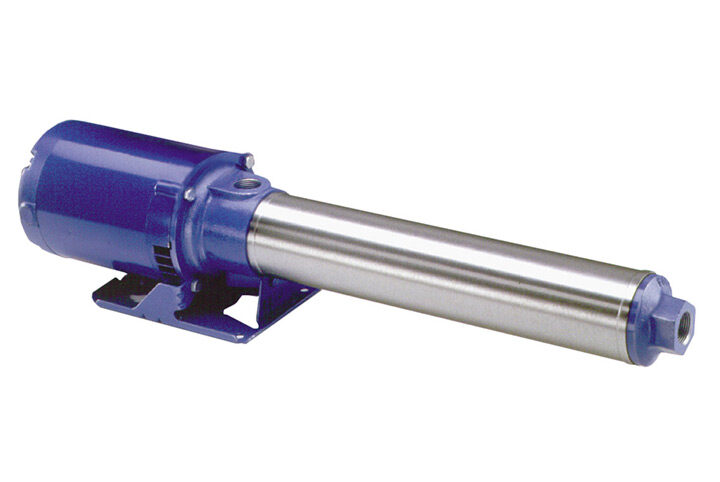

- Close-Coupled Design: Compact design saves space and simplifies installation.

- Casing Features: Investment cast 316 staniless steel construction with NPT threaded suction and discharge, optional drain and vent with stainless steel plugs. Four position discharge orientation.

- Mechanical Seals: Standard Flowserve 31 Seal with carbon versus with carbon versus silicon-carbide faces, Viton elastomers and 316 staniless steel metal parts. Optional seals are available for high temperature and mild abrasive services.

- Drive Motors: NEMA standard 56J frame motors with rudged ball bearing design for continuous duty. Versions are available in boh single and three phase with a variety of enclosures and voltage to match your service requirements

Applications

Designed for ultra pure water, chemical and general services. Specific uses are for:

- Washer Equipment

- Ultra pure water systems

- Scrubbers

- Chemical transfer

- Water reclamation and treatment

- Beverage processing

- Pharmaceutical service