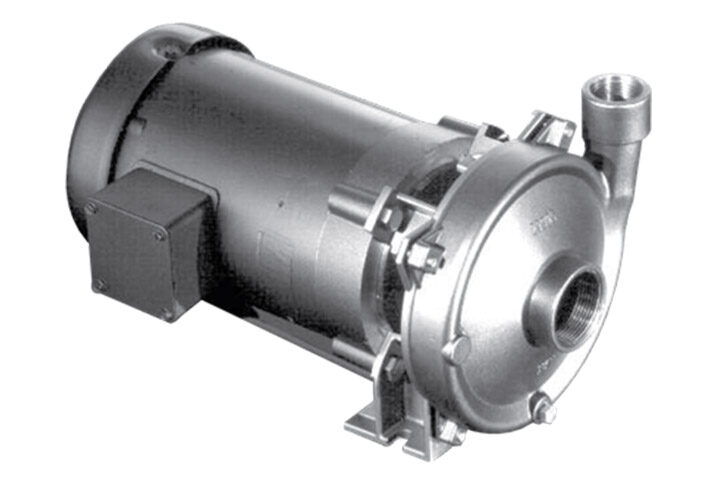

GOULDS 2ED/Dual Seal with Sensor Probe

Specifically designed for the following uses:

• Farms • Trailer courts

• Effluent systems

• Motels • Schools

• Hospitals • Industry

FEATURES GOULDS 2ED/Dual Seal with Sensor Probe

- Impeller: Cast iron, semi-open, non-clog with pump-out vanes for mechanical seal protection. Balanced for smooth operation. Silicon bronze impeller available as an option.

- Casing: Cast iron volute type for maximum efficiency. 2″ NPT discharge.

- Dual Mechanical Seals

- Lower: SILICON CARBIDE VS. SILICON CARBIDE sealing faces. Stainless steel metal parts, BUNA-N elastomers.

- Upper: CARBON VS. CERAMIC sealing faces. Stainless steel metal parts,BUNA-N elastomers.

- Seal Sensor Probe: Located in oil-filled chamber. If pumpage should begin to leak past lower seal it indicates to pump control panel a fault has occurred. Requires optional Seal Fail Circuit in the control panel

- Shaft: Corrosion resistant, stainless steel. Threaded design. Locknut on all models to guard against component damage on accidental reverse rotation.

- Fasteners: 300 series stainless steel.

.

Capable of running dry without damage to components.

Designed for continuous operation when fully submerged.

Specifications

Pump

- Solids handling capacibilities:3/4″maximum.

- Discharged size:2″NPT.

- Capacities:up to 128feet TDH.

- Temperature:104º F (40º C) continuous,140º F (60º C) intermittent.

Motors

- Fully submerged in high-grade turbine oil for lubrication and efficient heat transfer.

- Class F insulation

Single phase:

- Built-in overload with automatic reset.

- All single phase models feature capacitor start motors for maximum starting torque

Three phase:

- Overload protection must be provided in starter unit.

- ½-1½ HP – 14/4 STOW with bare leads.

- Designed for Continuous Operation: Pump ratings are within the motor manufacturer’s recommended working limits, can be operated continuously without damage when fully submerged.

- • Bearings: Upper and lower heavy duty ball bearing construction.

- • Power and Control Cable: Severe duty rated, oil and water resistant. Epoxy seal on motor end provides secondary moisture barrier in case of outer jacket damage and to prevent oil wicking. 20 foot standard with optional lengths available.

- • O-ring: Assures positive sealing against contaminants and oil leakage.