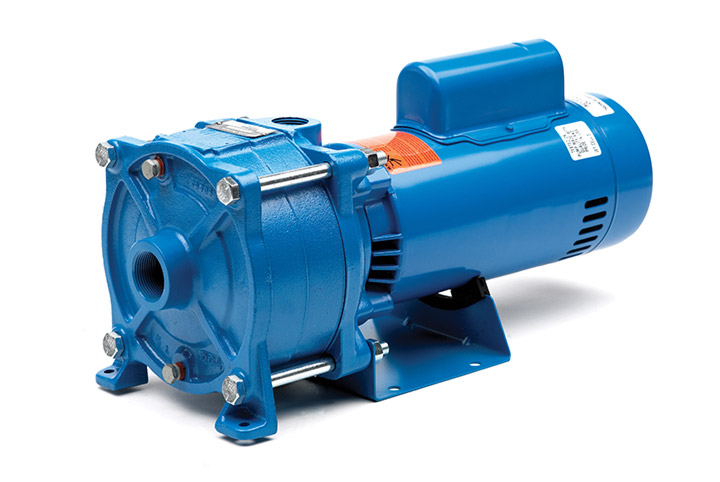

GOULDS HSC Centrifugal Pumps

G&L Series HSC

Applications:

- General purpose pumping Water circulation

- Booster service

- Liquid transfer

- Spraying systems

- Jockey pump service

Features

- Multi-stage Design: Provides steady, quiet and vibration-free operation for years of trouble-free service.

- Impellers: 20% glass-filled thermoplastic precision molded for high efficiences.

- Compact design: Close-coupled, spae saving design provides easy installation. Flexible coupling coupling and bedplate no required.

- Mounting: Can be mounted in vertical or horizontal position.

- Stainless Steel Pump Shaft: Hex design provides positive drive for impellers and eliminates clearance adjustments.

- Corrosion Resistant: Stainless steel wear rings and coverplates. Electro-coated paint process applied inside and out and then baked on.

- O-Rings: Throughout for positive sealing.

- Easy to Service: Can be taken apart for service by removing four bolts.

- Motor: Close coupled design. Ball bearings carry all radial/axial thrust loads. Designed for continuous operation. All ratings are within working limits of the motor. Available from ¾ – 3 HP.

Specifications

- Capacities: To 50 GPM

- Pressures: To 100 PSI (230 feet)

- Pipe connections: 11 ⁄4″ suction, 1″ discharge

- Temperatures: to 180°F (82°C) maximum

- Maximum working pressure: 125 PSI

- Rotation: right hand, ie; clockwise when viewed from motor end.

- NEMA standard,3⁄4 – 11⁄2 HP, 115/230 V;2 and 3 HP, 230 V, 60 Hz.

- Single phase ODP (standard)

- Three phase available

- 3500 RPM, ODP motors standard

- Built-in overload with automatic reset

- Capacitor type

- Stainless steel shaft

- TEFC and Explosion-proof motors available.

Motor