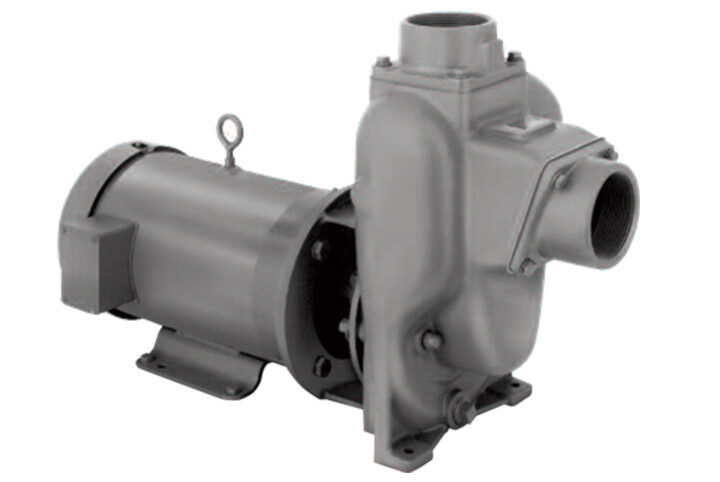

MTH T41 E41 Design Features (Continued) IP21 enclosure and range from 1/3HP to 2HP. All D3 motors feature a 304

stainless steel shaft and CE mark approval. T41 pumps can accept most commonly available motors through the use of close or flexible coupling.

For wider fluid compatibility, T41 units 3HP and under feature a protective motor shaft sleeve, while motors 5HP and over utilize a corrosion-resistant

316 stainless steel shaft.

Near-constant capacity is maintained over wide variations in pressure. High shut-off pressure overcomes temporary line resistance.

Self-Adjusting Impeller

A hydrodynamic film on each side of the impeller positions it for long life.

The impeller exerts no thrust load on bearings. Pump operates equally well in a vertical or horizontal position.

Mechanical Seals

Bronze fitted pumps have Buna N elastomers, high temperature carbon, and ceramic seats for best hot water

service. Optional seats and materials are also available.

300# Case Working Pressure

Rigid structure is designed for maximum casing strength.

100% Tested

Every pump is fully tested to verify performance prior to shipment.

Volatile Fluid Handling

Turbine impeller handles vapors in excess of 20% by volume, minimizing the possibility of vapor locks.

”O”Ring Gaskets

“O”ring seals are used throughout the E41/T41 Series pumps to assure sealing and ease of service.

Shaft Sleeve

T41 pumps with motors 3HP and under utilize a protective shaft sleeve of an appropriate metallurgy according to the Standard Materials table.

Motors 5HP and over have a 316 stainless steel shaft with an impeller bushing as listed under Standard Materials. E41 pumps do not utilize a shaft sleeve due to the use of a standard 304 stainless steel motor shaft.

Water Flinger

A water flinger provides added protection to ball bearings in the event of seal leakage.

Simple Construction

E41/T41 Series pumps contain only three major components, allowing for easy service.

End Suction • Top Discharge

E41/T41 Series pumps fit into small spaces easily. Discharge can rotated to 90 degree, 180 degree and 270 degree positions.

Best Efficiency

New pump design optimizes efficiency for each size.

Non-Cavitating

E41/T41 series pumps may be operated under adverse inlet conditions without audible or measurable cavition.

Low NPSH

New inlet design provides superior fluid handling ability at low head inlet conditions.